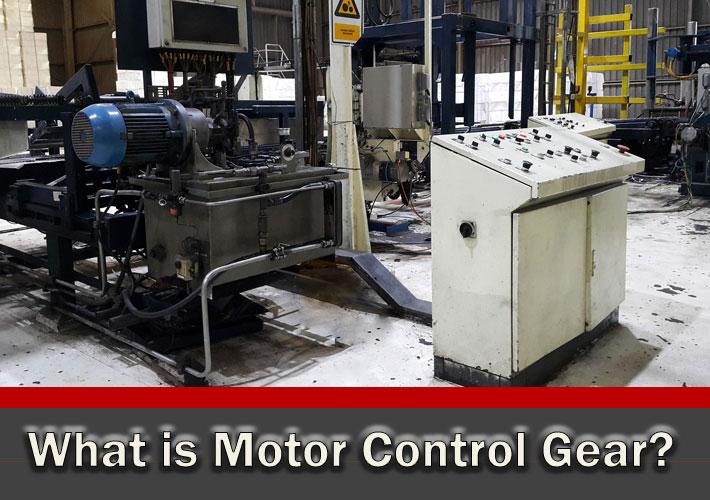

What is Motor Control Gear?

Motor control gear is a selection of industrial electrical components such as contactors, overloads and inverter drives that help to control the speed of a motor. A motor doesn't always need to run flat out at 100%, motor control gear helps you take to control and protect the motor from being driven too hard.

When driven too hard, an electrical motor can produce high torque or too much force while can cause damage and downtime. Motor control gear can slow down the speed and reduce the horsepower/kilowatt consumption. Motors are use in lots of diverse applications, ranging from wind turbines to washing machines.

Typically, gear motors are used in devices like garage door openers, control knobs on your washing machine, electric alarm clocks and even in that simple can opener. The common usage in commercial applications includes cranes, commercial jacks, and hospital beds, among very many others.

How does it Work?

Primarily, control gear motor is used to reduce speed in a gear series, which in turn creates additional torque. This gets achieved through a gear box or an integrated gear series getting connected to the main shaft and motor rotor via a 2nd reduction shaft. Then the 2nd shaft is linked to the gear box (or gear box series) to create what’s referred to as a reduction gear series. In principle, the longer the reduction gears train or series, the lower will be the output of the final.

A very good illustration of the motor control gear principle is the electric time clock using seconds, minutes and the hour hands. A synchronized AC motor employed in powering the clock usually spins the rotor at about 1500 revolutions each minute. Because, the hands would be moving very fast and at same speeds, a reduction gear series is employed in slowing down the clock hands movements.

In commercial applications, they are commonly used in situations where an equipment piece needs to have the capacity of exerting high quantities of force so as to shift or move an extremely heavy object. Good examples of such application would be the lift jack.

Types of Motor Control Gear

- Electrical contactors - Can be used individually or wired in specific formations with other accessories like timers or thermal overloads. These other formations include DOL (Direct on Line), reversing starters and Star-Delta starters.

- Inverter drivers - A more advanced form of motor control that is more digital than mechanical. Providing you with a more precise way of controlling the speed of your motor. Speed drives are classed as an energy saving device as they make your motor operate more energy efficiently.

Bottom Line

If you have watched a crane in operation, then you have seen the best example of the way a motor control gear works. The motor employed in most cranes is the typical gear motor type that utilizes the basic speed reduction principles to increase force or torque.