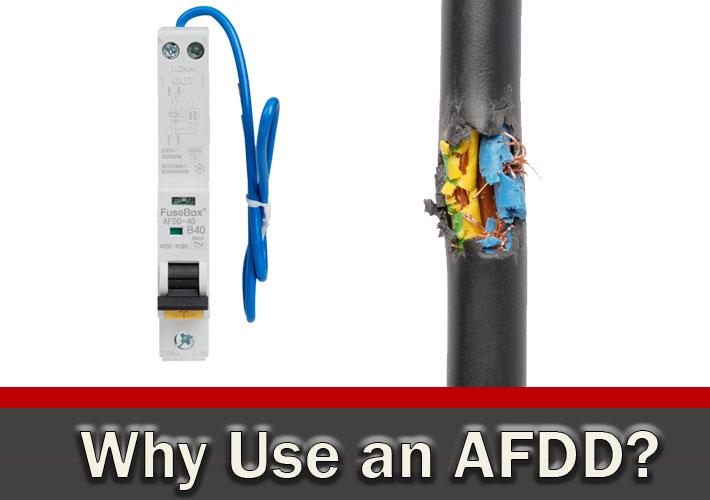

Why Use an AFDD?

In the United Kingdom, faulty domestic appliances and leads caused 19,300 accidental fires. Fires of this sort often spring from electric arcs, overheating, loose cable, broken cables, deterioration of cable isolation, to name a few. Unfortunately, all these electrical faults are challenging to detect, and regular circuit breakers, fuses and residual current devices – may not always notice or respond to the minor arc faults that have the potential to cause a fire. The good news is, with the installation of an Arc Fault Detection Device (AFDD), these types of electric fires can be avoided.

What is an AFDD?

An Arc Fault Detection Device (AFDD) at its core is a circuit protection device. It’s like miniature circuit breakers (MCB) and residual current devices (RCD’s) but provides a different kind of protection. AFDD’s are microcomputers that sit with or combined with an overcurrent protective device. They made this device to look for the signature of an electrical arc (or spark).

How Does it Work?

The AFDD constantly monitors and analyses patterns in electrical current and voltage waveforms. It watches for random, non-predictable yet persistent patterns that indicate a dangerous arc. It uses electronic technology and an algorithm to analyse the signature of the waveform of an arc, so it detects the difference between normal arcing and arcing faults. You can use an AFDD with a circuit breaker or an RCBO ( residual-current circuit breaker with overload protection). It can also have its switching function.

AFDD can analyse abnormal arc forms through:

- The signature of the arc

- Duration of the arc. As an example, very short durations are characteristic when you turn a switch on or off.

- Irregularity of the arc

When it detects an abnormal arc wave pattern, it trips, isolating the faulty circuit. It’s designed to react quickly because an electrical arc can degrade swiftly and ignite surrounding flammable materials and cause a fire.

AFDD’s are tested by their manufacturers and designed to recognise normal arcing from normal equipment operations like vacuum cleaners, dimmers switches, drills, etc., or from normal sparks from unplugging and plugging general electrical equipment. So it’s sensitive to irregular arcs but not too sensitive that it shuts down every time a vacuum or a drill is used.

What are Arcing Faults?

Before we discuss arcing faults, let’s quickly define what an arc is. An arc is a visible plasma discharge caused by an electrical current passing through air when it jumps a gap in an electrical circuit.

An AFDD detects arcing faults, but what are arcing faults? An arc fault happens when loose wire connections or corroded wires cause sparking or arcing. This arcing creates heat which can cause an electrical fire.

An arc fault can come in the form of:

- Series arc fault. This type of fault commonly comes from crushed, broken or damaged cables.

- Parallel arc fault. These arc faults can develop from pierced insulation, rodent damage, UV deterioration, old insulation, thermal damage.

An arc fault can develop instantly (over an hour, for example) or over a long period (weeks, months, even years). Regardless of how it develops, the critical thing to remember is that a developing arc can produce temperatures over 6000 centigrade. This temperature is enough to burn the surrounding insulation and start a fire.

Why Use an AFDD

Currently, an AFDD is not a requirement in electrical installations in the United Kingdom, although it’s been around for quite a bit. Although it’s not a legal requirement, it is highly recommended for increased safety and protection against unintended fire as per regulation BS7671.

Electric arcs in cables and connections, especially those hidden from view, cannot be detected by fuses, circuit breakers, or residual current devices. Undetected, faulty arcing can cause a fire. As discussed above, an arc fault detection device (AFDD) disconnects the circuit’s electricity supply when it detects the presence of dangerous electric arcs.

The following are suggested places where an AFDD can be installed:

- Barns, stores with combustible materials, woodworking shops.

- Places with sleeping accommodations like houses, hotels and inns.

- Wooden buildings or areas with flammable construction materials.

- Places with irreplaceable goods like museums, historical buildings.

Installing an AFDD

There are two scenarios in the real world where an AFDD can be installed. Let’s take a look at these scenarios.

- Installing an AFDD in a new fuse box. It’s highly recommended to install an AFDD breaker with integrated RCD and MCB protection functionality. In this way, your client can be assured of maximum protection while fully complying with BS7671 regulations.

- Installing an AFDD in an existing fuse box. If your customer has old cabling buried inside your walls, most probably, it doesn’t comply with the BS7671 standards. It can even be old and frayed and needs to be replaced. If you have clients upgrading their home with a hot tub, new TV or entertainment systems, you may need to upgrade their fuse box. You’ll need to do a visual inspection as well as look at expired certifications for existing electrical devices. With an AFDD, all electrical faults with the new and existing appliances will be fully detected and protected.

Types of AFDD

There are various types of AFDD on the market, each with its own characteristics. Generally, regardless of the brand, there are four types of AFDD:

- Standalone AFDD

- AFDD integrated with an RCBO ( Residual Current Circuit Breaker)

- AFDD integrated with an MCB ( Miniature Circuit Breaker)

- AFDD Add on Module

Fires can cause a lot of damage to property, worse it can even cost people their lives. The installation of an AFDD can help prevent another fire caused by faulty wiring, and in the process, save money, irreplaceable properties, and even lives. Remember, an ounce of prevention is worth a pound of cure.

6 Comments